-

The Die Station is moveable in Up and down directions via the adjustment system. 2 t0 6 heating zone with Easy handling Heater system make multi die adjustments for better product profile. All heaters would be controlled by the PID controller

-

Pulling and gripping force is provided by a reliable and powerful twin puller auto hydraulic system. Smooth and continuous operation is made possible by the flow & propositional derivative valve controls that are regulated by the PLC. An integral water-cooled oil heat exchanger unit is installed to maintain safe operating temperatures and ensure long system life. Although the hydraulic system is largely computer controlled, the operator is still capable of controlling system pressure, puller pressure and gripper pressure with speed.

-

PLC controller system of Siemens/ Omron / Schneider make is provided to operate the machine. Digital read out and control for the pulling speed, heating temperature of the die, cutting length etc by PLC system with computer communication. Synchronizing and accurate speed linear scale with high resolution is provided to give the accurate feedback to the PID valve and maintain the constant speed irrespective of the load.

-

Container that holds thermoset resin at the beginning of the pultrusion machine; made from stainless steel sheet metal with a tubular mild steel frame. Each bath capacity is 30 lit.

Mild steel racks placed before the carding stand, which hold rolls (bales) of fiberglass roving for entry into the carding stand. These racks maintain proper roving alignment and prevent roving entanglement

-

PLC Synchronizing and accurate speed linear scale with high resolution is provided to give the accurate feedback to the cutsaw and maintain the constant speed.

Product Details

We offer Pultrusion machinery, equipment and ancillary services, to cater to the diverse needs of our clients and customers. Some of the impressive benefits of our equipment are listed below:

- Quality Components

- High Pull Speeds with accurate auto control

- Ease to Operation

- Heavy Duty Construction

- High performance

Kana Advanced Composite Industries is a manufacturer of high quality, durable pultrusion machines and equipment. Our machines are built using the one of the best technology available in Composite world with law cost. The company philosophy is to engineer our pultrusion machines to exceed the customers’ expectations.

In addition to the machine specifications listed below, Kana Advanced Composite Industries Pultrusion can design and build new pultrusion machines to meet your specific product or process requirements. Let our experience in engineering and manufacturing Pultrusion and pultrusion equipment benefit your organization.

SECTION OF THE MACHINE:

Die and Heating Zone :

The Die Station is moveable in Up and down directions via the adjustment system. 2 t0 6 heating zone with Easy handling Heater system make multi die adjustments for better product profile. All heaters would be controlled by the PID controller

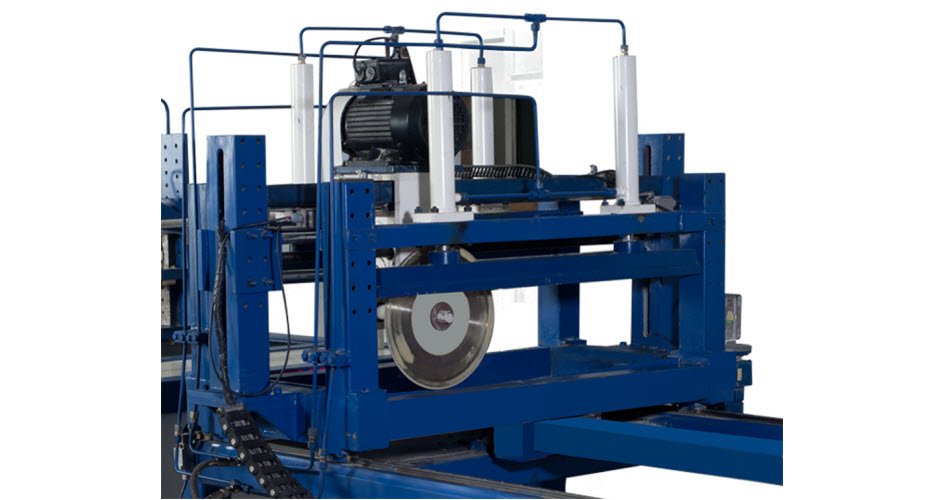

Pulling and Gripping System :

Pulling and gripping force is provided by a reliable and powerful twin puller auto hydraulic system. Smooth and continuous operation is made possible by the flow & propositional derivative valve controls that are regulated by the PLC. An integral water-cooled oil heat exchanger unit is installed to maintain safe operating temperatures and ensure long system life. Although the hydraulic system is largely computer controlled, the operator is still capable of controlling system pressure, puller pressure and gripper pressure with speed.

Control and Measurements System :

PLC controller system of Siemens/ Omron / Schneider make is provided to operate the machine. Digital read out and control for the pulling speed, heating temperature of the die, cutting length etc by PLC system with computer communication. Synchronizing and accurate speed linear scale with high resolution is provided to give the accurate feedback to the PID valve and maintain the constant speed irrespective of the load.

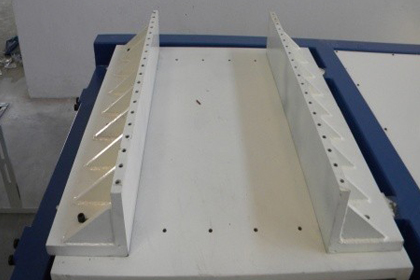

Resin Impregnation and Creel Rack :

Container that holds thermoset resin at the beginning of the pultrusion machine; made from stainless steel sheet metal with a tubular mild steel frame. Each bath capacity is 30 lit.

Mild steel racks placed before the carding stand, which hold rolls (bales) of fiberglass roving for entry into the carding stand. These racks maintain proper roving alignment and prevent roving entanglement

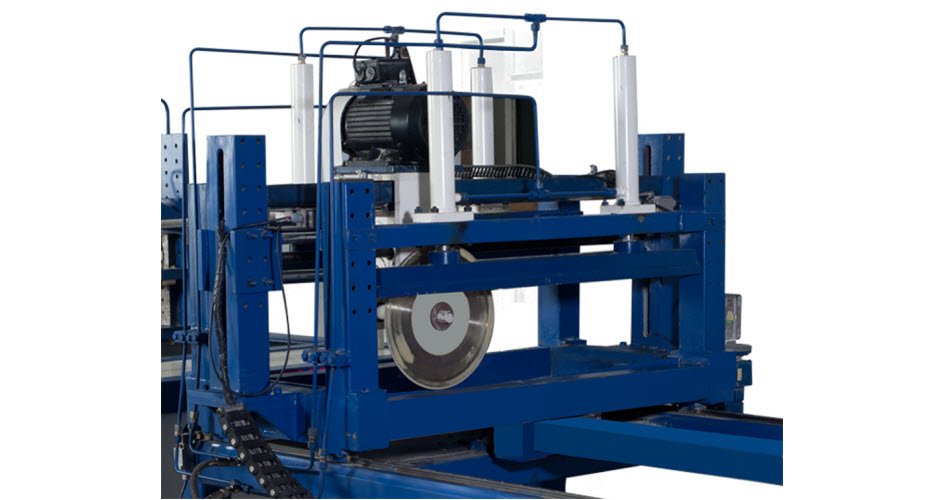

AUTO CUT SAW:

PLC Synchronizing and accurate speed linear scale with high resolution is provided to give the accurate feedback to the cutsaw and maintain the constant speed.

SAFETY / ENVIROMENT FEATURES:

- Fully Guarded and cover drives and slide ways.

- Fully guarded Saw.

- Stop and Emergency Stop Button provided to stop the machine in case of emergency.

- Low Noise Output.

TCHONOLOGY SUPPORT

In addition with the machine , Kana Advanced Composite Industries offered to support total solution of formulation and production to meet your product with global standard like ASTM, CTI, BS and NEPHA.

Pultrusion Machine